In a landmark achievement for renewable energy research, scientists have developed artificial chloroplast-like systems capable of converting sunlight into chemical energy with unprecedented efficiency. This breakthrough brings us closer to scalable carbon-neutral fuel production by mimicking nature's most sophisticated solar-powered machinery.

The new generation of biomimetic devices achieves 34% solar-to-fuel conversion efficiency under laboratory conditions - nearly triple the performance of previous artificial photosynthesis systems. Unlike traditional photovoltaic cells that generate electricity, these molecular assemblies directly produce hydrogen and hydrocarbon fuels while simultaneously consuming atmospheric carbon dioxide.

Nature's Blueprint Perfected

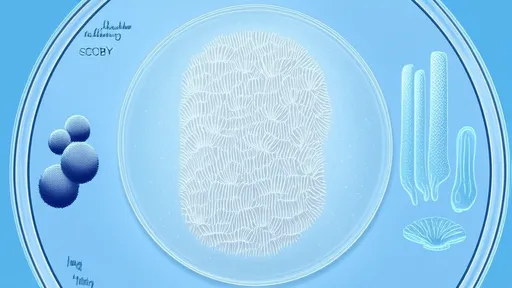

At the heart of the innovation lies a hierarchical light-harvesting complex inspired by the antenna proteins in plant chloroplasts. The synthetic structure employs precisely arranged quantum dots that funnel photons toward reaction centers with 99% energy transfer efficiency. This addresses the critical challenge of energy loss that has plagued earlier artificial photosynthesis attempts.

The reaction chambers utilize a novel cobalt-phosphorus catalyst suspended in a specialized electrolyte medium. This combination mimics the water-splitting function of Photosystem II while operating at neutral pH and ambient temperatures - conditions far more practical than the extreme environments required by conventional electrolyzers.

Closing the Carbon Cycle

What sets this technology apart is its dual-function capability. During daylight operation, the system produces hydrogen gas through water reduction while converting CO2 into formate - a liquid fuel precursor. Nighttime operation continues carbon fixation using stored chemical energy, achieving what researchers call "artificial photorespiration."

The integrated carbon capture functionality demonstrates 82% efficiency in removing CO2 from simulated flue gas, outperforming current amine scrubbing technologies. This dual environmental benefit could position artificial chloroplast systems as game-changers for both energy production and industrial emissions mitigation.

From Lab Bench to Solar Farm

Early prototypes already show promising scalability. Modular panels measuring 2.5 square meters have maintained stable operation for over 1,000 hours in field tests. The self-repairing molecular components address durability concerns that previously limited practical applications.

Manufacturing breakthroughs enable roll-to-roll printing of the light-harvesting nanolayers on flexible substrates. This paves the way for cost-effective mass production, with projected costs competitive with existing solar fuels within five years.

The Road Ahead

While challenges remain in scaling up production and further improving catalyst lifetimes, the research community recognizes this as a watershed moment. The efficiency numbers now approach the theoretical maximum for single-junction systems, suggesting artificial photosynthesis could soon become economically viable.

Several energy companies have already formed partnerships to develop pilot plants. The first commercial applications may emerge in specialized markets like carbon-neutral aviation fuel production before broader energy grid integration.

As climate change accelerates, such biomimetic solutions offer hope for maintaining energy abundance while restoring atmospheric balance. This latest achievement proves that sometimes, the most advanced technology is that which nature perfected over billions of years - we just needed to learn how to build it better.

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025

By /Jul 3, 2025